Add to Cart

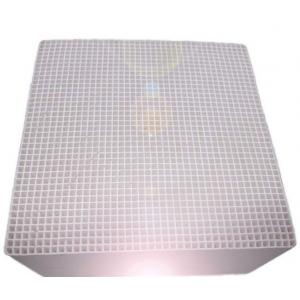

Gas Honeycomb Ceramic Substrate With 3 Way Catalytic Converter

Description:

After coated with catalyst, the product is widely applied in organic waste gas purification, heat exchange system industrial waste gas treatment, coal-fired power plant flue gas purification, NOx purification system, garbage incineration and harmful gas purification treatment, etc.Benefits of Products:

● Large Surface Area

● Low thermal expansion coefficient

● Good thermal shock and thermal shock performance

● Good corrosion resistant performance

2 1.Product use

After coated with catalyst, the product is widely applied in organic waste gas purification, heat exchange system industrial waste gas treatment, coal-fired power plant flue gas purification, NOx purification system, garbage incineration and harmful gas purification treatment, etc.

2.Overall dimensions standards

| Item |

| Standard values | Allowance | Remark |

| boundary dimension | length | 150MM | ±1.5MM |

|

| width | 150MM | ±1.5MM |

| |

| height | 50-100MM | ±1.0MM |

| |

| 101-300MM | ±1%MM*height |

| ||

| verticality | height | 50-100MM | ≤1MM |

|

| 101-300MM | ≤1%Height |

| ||

| parallelism | height | 50-100MM | ≤1MM |

|

| 101-300MM | ≤1%height |

|

| Item | Standard values

| Test methodS

| ||

| chemical component

| Al2O3 | 35.2%±1% | Chemical titration analysis | |

| SiO2 | 50.9%±1% | |||

| MgO | 13.9%±1% | |||

| Cordierite main crystalline phase content | ≥90% | X-ray diffraction | ||

| RT Mpa | AAxis | ≥15 Mpa | universal material testing machine | |

| BBxis | ≥2 Mpa | |||

| water absorption | 23%-27% | Gravimetric method | ||

| softening temperature | ≥1320℃ | high-temperature electric resistance furnace | ||

| CET(800℃) | ≤1.6*10-6/℃ | thermal dilatometer | ||

Applications:

After coated with catalyst, the product is widely applied in organic waste gas purification, heat exchange system industrial waste gas treatment, coal-fired power plant flue gas purification, NOx purification system, garbage incineration and harmful gas purification treatment, etc.

Specifications

| Cell density (CPSI):7~400 | ||||

|

Item | (mm) Sectional Dimension | (mm2) Area of Section |

Shape of Section | (mm) Height |

| 1 | 50×50 | 2500 | |

The height can be designed by customer |

| 2 | 50×50 | 2500 | | |

| 3 | 100x100 | 10000 | | |

| 4 | 150x150 | 22500 | | |

REMARK: The SIZE can be designed by customer

Competitive Advantage:

● Large Surface Area

● Low thermal expansion coefficient

● Good thermal shock and thermal shock performance

● Good corrosion resistant performance